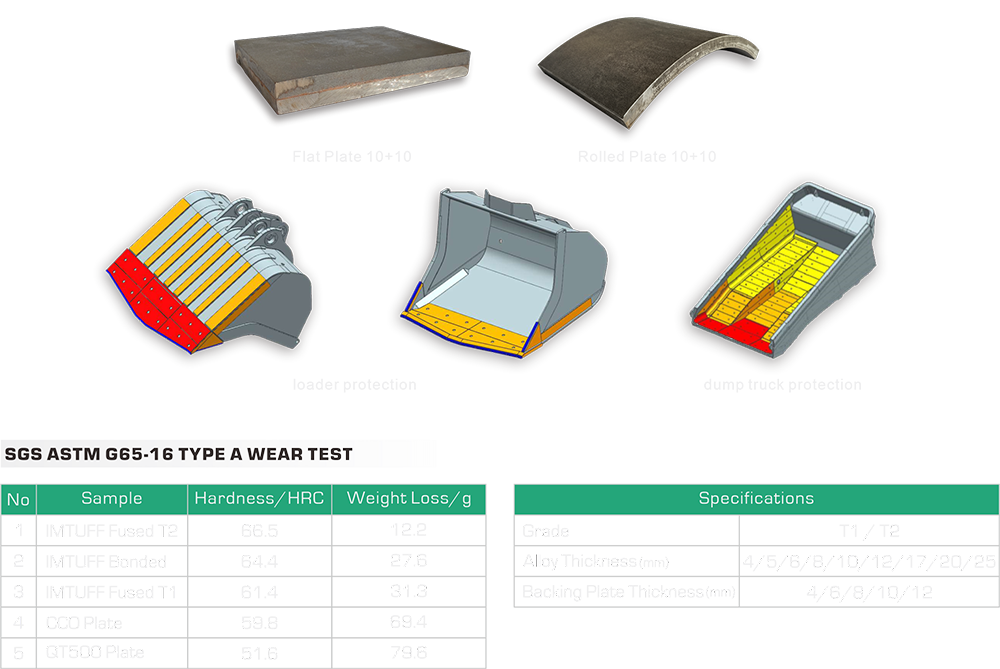

IMTUFF® Composite Plates, Blocks & Bars

IMTUFF™ Fused Bi-metal Plate is excellent alternative to the conventional chrome carbide overlay (CCO) plates. It is targeted at different types of wear in the mining, cement, power generation and steel industries, such as abrasion, impact, heat and erosion wear. It is also great solution for wear protection package for mobile equipment sucha as loaders, excavators and dump trucks.

The unique manufacture process includes the use of plasma rotating electrode process (PREP) that applies alloyed powder on mild steel plate; the combined technology of laser engineering net shaping (LENS) and wire arc additive manufacturing (WAAM) that creates molten pool, and the rapid solidification process without causing any crack. It provides a smooth surface finish which means less friction and reduced material hang-up.

The IMTUFF™ Fused Bi-metal Plate features uniform microstructure and even hardness distribution (up to HRC66) from top surface down to the fusion line, which is critical to providing excellent abrasion and impact wear resistance. The IMTUFF™ Fused Bi-metal Plate is available in various grades to suit different applications. It can be rolled due to the low residual stress between the mild steel and the ultra-hard alloy. It can be also machined to have countersunk or tapered holes.

View Our Other IMTUFF Wear Solutions Products