Manganese Crusher Liners

TEMPUS offers a comprehensive range of premium quality replacement wear parts for the world’s leading crusher brands for the mining and aggregate operations across the globe. Our state-of-art foundry produces crusher wear parts in a range of austenitic manganese steel from 14% to 26% manganese grades together with chromium and molybdenum alloyed grades. Latest technology heat treatment methods are utilized to achieve optimum toughness and wear-resistant properties.

|

Through our wealth of engineering and metallurgical expertise, combined with the latest foundry technology and rigorous quality control, we are able to add value to our customers by reducing production cost per ton. Our crusher liners, including cone, jaw and gyratory crusher liners, are manufactured in green and low carbon footprint environments. Unique Features of our manganese |

Standard Jaw, Cone & Gyratory |

|

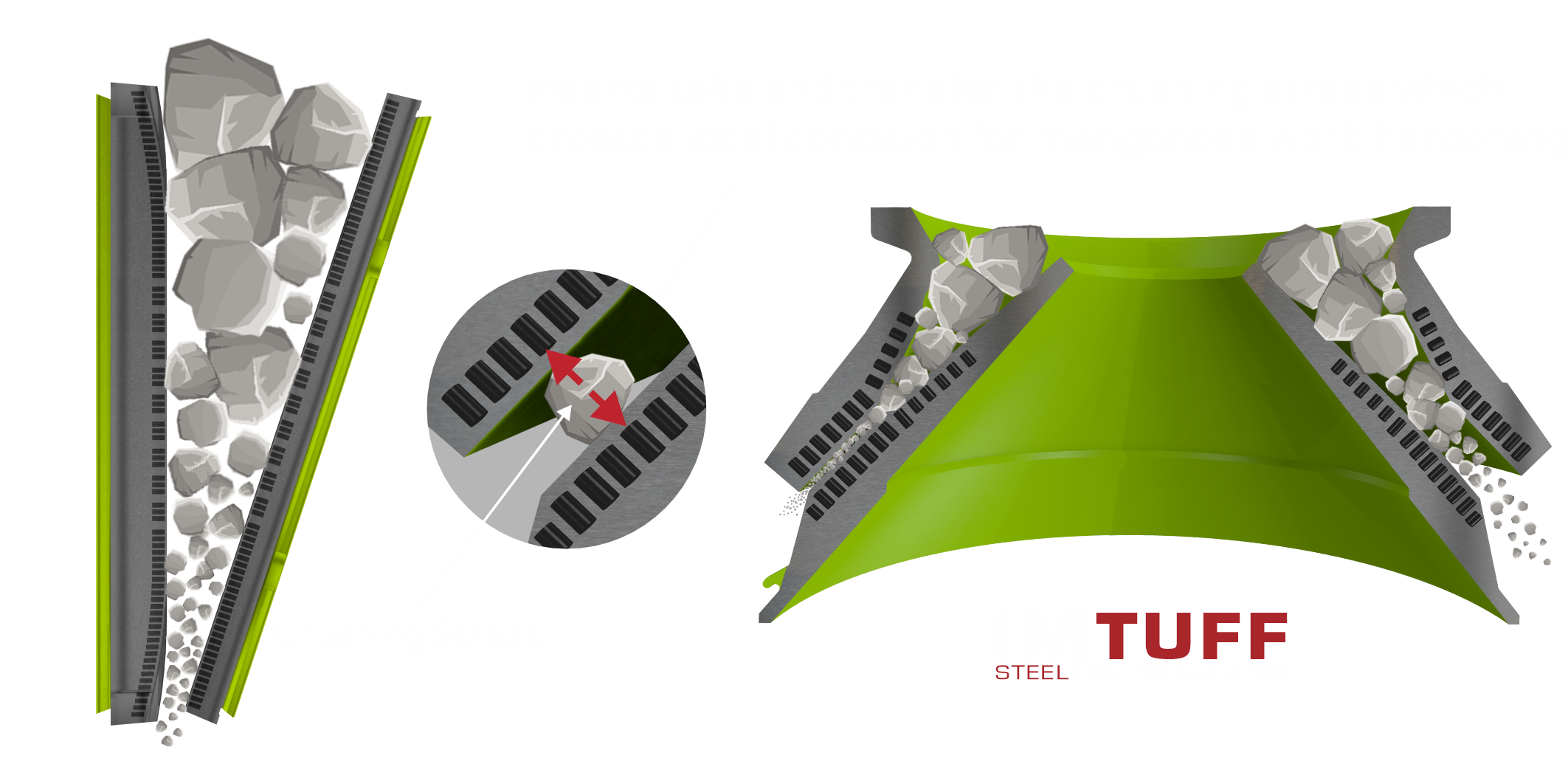

IMTUFF® TIM Crusher Liners |

TEMPUS also developed the unique and patented IMTUFF® TIM liner technology which is applied to the primary, secondary and tertiary crushing.

|

Gallery of Images

View Our Other Product Ranges

Strict and precise chemical composition

Strict and precise chemical composition